So far, most innovations in RFID technology have been geared towards the possibilities in warehouse management as well as in parking systems and toll road payments. However, there is another area where RFID can contribute equally well, and that is supply chain security.

With costs associated with RFID tags decreasing, more and more manufacturers and distributors are adopting RFID technology to smoothen and secure their supply chain process. RFID devices can be used to track any number of assets during the entire supplying process — from allocation to ship-to-store operations to inventory management.

To understand the importance and use of RFID technology in supply chain security, let’s first see what the supply chain process is, and how it works.

What Is The Supply Chain Process? How Does It Work Without RFID?

In layman’s term, a supply chain is basically the flow of materials, information, products, and services from the procurement point until the end-user point. It is an integral part of any business, and for a long time, has been conducted using barcode machines and manual interventions.

In many supply chains, a barcode system is used to scan and collect the data, while others enter the data manually. Both these methods are slow and error-prone and using them to scan large volumes of items can result in a mismatch between the physical inventory and the system inventory. This leads to bottlenecks and poor visibility, which in turn affects the decision-making process and eventually slows down the overall production.

How Does RFID Help Increase Supply Chain Security?

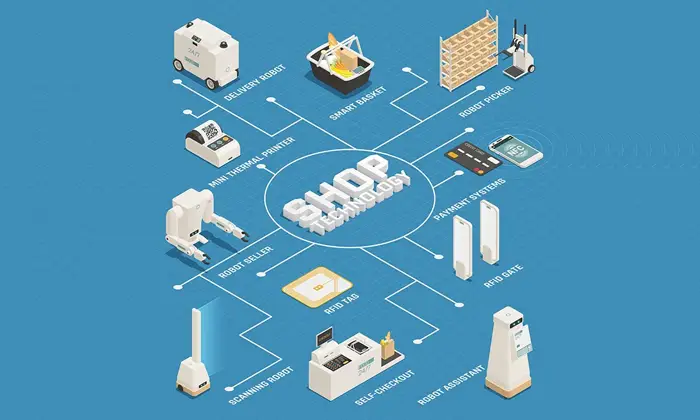

RFID consists of tags containing electronically stored information and readers that automatically identify and read the tags using electromagnetic fields. This provides RFID applications the capability to automate product identification in a supply chain process, leaving little room for security compromise and mishaps. RFID also helps pinpoint any lingering issues and streamline the operations effectively.

With RFID, businesses can ship items worldwide while keeping track of their storage conditions like temperature and humidity. RFID also increases security by providing continuous updates on the goods’ status and location and ensuring that they reach their destination at the right time.

To sum it up better, here are the reasons why RFID is a must-have for supply chain management.

- RFID helps in demand planning by providing real-time and accurate data on goods – whether they are in-progress, in-transit, or finished.

- RFID helps reduce inventory and order errors, increasing product visibility, and minimizing production delays.

- RFID tags are reusable assets that can be used on even the most difficult-to-track assets, such as trays, pallets, and containers.

- RFID does not require a direct line of sight or contact and can be operated from several meters. This provides a high level of data integrity to the users.

- RFID readers instantly alert you in case any attempt has been made to remove a tagged asset from an authorized area, increasing security.

- RFID is automated and needs almost no human intervention.

- RFID is a time-savvy, cost-effective technology that helps in faster invoice settlement, minimizes human error and simplifies the supply chain management process.

While all this sounds good, implementing RFID technology in the supply chain process does have its own setbacks. The major one being the high initial costs and restructuring costs that are required to update an existing analog system. Still, it will be exciting to see how this promising, rapidly evolving solution will advance in the near future – which seems bright as of now.