Having a robust asset tracking system in place protects not only your bottom line but also makes your business operations so much easier and efficient. How? By reducing redundancy, minimizing the scope of human error, and reducing asset losses or theft. Such efficiency gains, in turn, enable your business for unprecedented levels of productivity by empowering your staff with data and the ease of accessing the tools or resources they need to perform the job at hand.

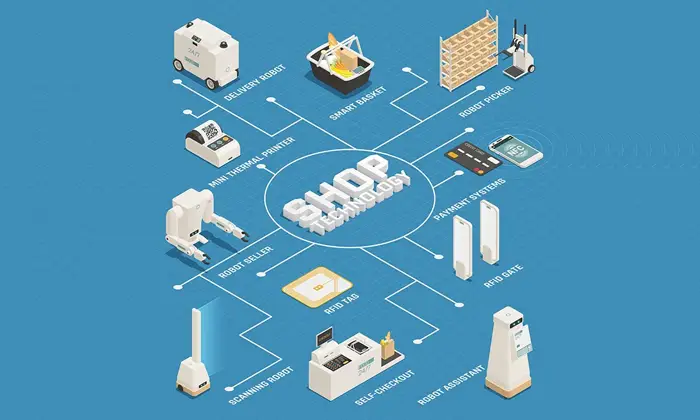

For asset management, RFID has proven to be a highly evolved and successful technology in the market. Manufacturing industries, transport sector, construction, and retail – nearly all types of industries are leveraging this technology. RFID-based asset tracking and management can have endless important business benefits.

RFID Brings Automation And Reduces Human Action

Unlike the traditional barcode-based tracking systems that required a significant ratio of functions to be performed by humans, RFID technology does not assign a lot of jobs to your employees. Scanning a barcode label requires the employee to carry a barcode scanner and directly point it at the tag, which can be hard to reach in large assets. With RFID, the reader can be placed several feet away and still obtain an accurate scan of the tag. Instead of placing several employees with separate scanners, you can now put a broad-range RFID reader to scan multiple assets in just a matter of seconds, without worrying about achieving a line-of-sight between the tags and your scanner.

Advanced RFID tags also come with an on-board data storage capacity, like an in-built memory chip, which can store crucial information related to the asset. When in remote locations with weak or zero connectivity to a cloud server, a database, or any kind of back-end applications, the necessary updates about maintenance activities can be stored directly on the tag. This new information can be written on the tag and, later on, read or accessed by any authorized field technician with the use of a mobile computer.

The many advantages include:

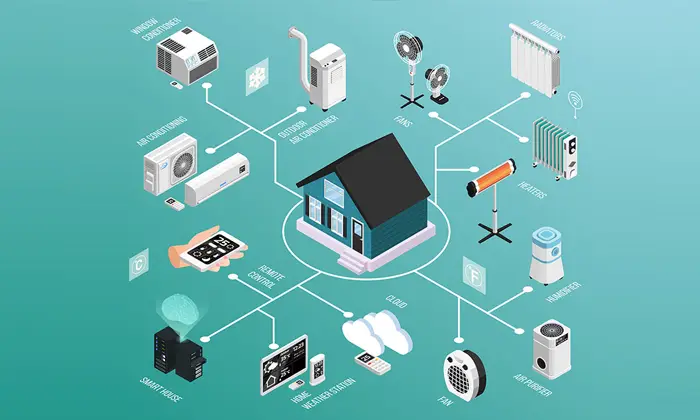

- When integrated with motion sensors and GPS technology, RFID tags can also be used to relay information related to an asset’s condition in addition to providing its real-time location updates.

- An RFID-powered asset tracking system can be connected with a wireless LAN to detect and trace assets remotely within a few seconds.

- The labor cost involved in inventory management is reduced as fewer employees are required to do the job. Also, the time spent reduces from days to hours.

With RFID automating crucial tasks, you can complete important tasks in less time, speed up other functions, and significantly reduce labor costs related to the tracking of your inventory and assets. You will have more time, resources, and peace of mind to work towards improving your bottom line.

RFID Enables Real-Time Asset Visibility

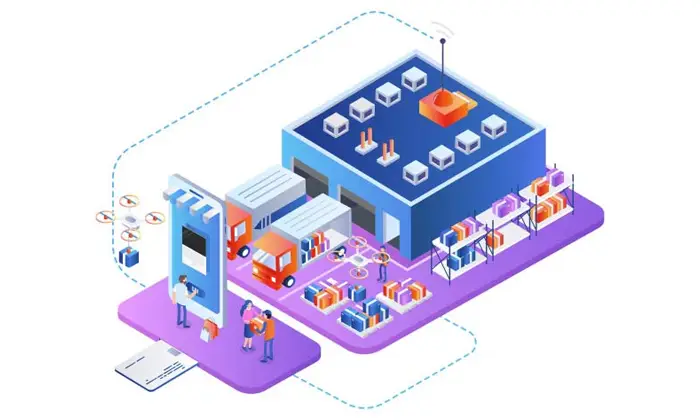

In most businesses, assets continuously enter and exit the facility. Between those two points, your items can be out of radar, which involves an element of risk. RFID works to make this in-transit process transparent, allowing you to manage what is out of sight by keeping it in your knowledge. All of these functions can be performed in real-time. A cloud-based RFID asset tracking system not only allows you to track your inventory but also learn all about the movement of your trucks, forklifts, returnable transit items, and other valuable assets that frequently move in and out of your location.

Also, RFID tags can be read from anywhere within your business premises to obtain valuable information, such as the quantity of an item, its current location, and the previous movements. This gives you whereabouts and previous shipment details associated with all the instances when the said item has left the building. As a result, businesses can utilize this information to learn about and resolve issues arising due to oversight, mismanagement, misplaced materials, and errors related to manual processes. It gives you the flexibility to take important decisions on the fly and make immediate changes, like rerouting an item when stuck in a process.

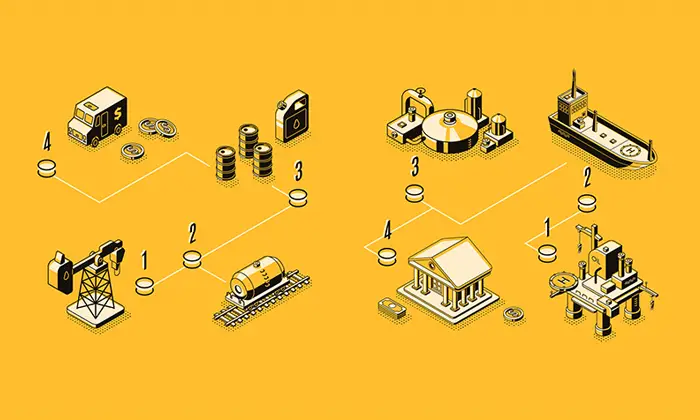

RFID Eliminate Delays In Deliverables Or Product Deliveries

A business’s reputation is built on its ability to honor deadlines and fulfill expectations. However, what goes behind is the on-going struggle to prevent delays. It is a challenge to fight bottlenecks that rear their ugly heads from time to time and maintain an efficient production flow with the goal of achieving optimal output every day.

Now, what will happen if there is a lack of visibility of an item moving through the stages of production and distribution? Problems are communicated and resolved at a much slower rate due to the dependency on manual functions. In turn, products don’t reach the place they are required to be, and at the time they are supposed to be. Consequently, delays can lead to wasted labor effort, added expense, weakened customer confidence, and/or an increased stock of unwanted items.

However, by automating the process through RFID tracking, you can improve asset visibility, resolve problems in a timely manner, eliminate bottlenecks, and even exceed expectations by accelerating delivery times.